Thermal Barrier Coating Thickness on Carbon Fibre Reinforced Plastic (CFRP)

A new method to monitor Thermal Barrier coating quality on CFRP.

Challenge: In the Growing Use of Composites in Aerospace

In today’s aerospace and space sector, the carbon fibre-reinforced plastics (CFRPs) plays a vital role because of its efficient properties such as high specific strength and stiffness, good fatigue, and chemical resistance which are much need for structures integrity. The majority of commercial airplanes are from Boeing 737, 747, 777, 787 and Airbus A320, A330, A350, A380. The goal of the International Civil Aviation Organization (ICAO) is to reduce aviation emissions by at least 50% by 2050. So, the development of composites with lightweight materials, namely CFRP, will increase. The modern aircrafts like Boeing 787 and Airbus A380 use more than 50% of CFRP in aircraft structures. To fully utilize on CFRP benefits under which thermal protection is crucial. The polymer matrix, which binds with the carbon fibers are vulnerable to heat-induced decomposition. Safeguarding CFRP from high temperatures and frictional forces are vital. CFRP is now being an integral part of advanced satellites, launch vehicles, and space exploration missions which will also need to sustain from drastic temperatures and frictional forces.

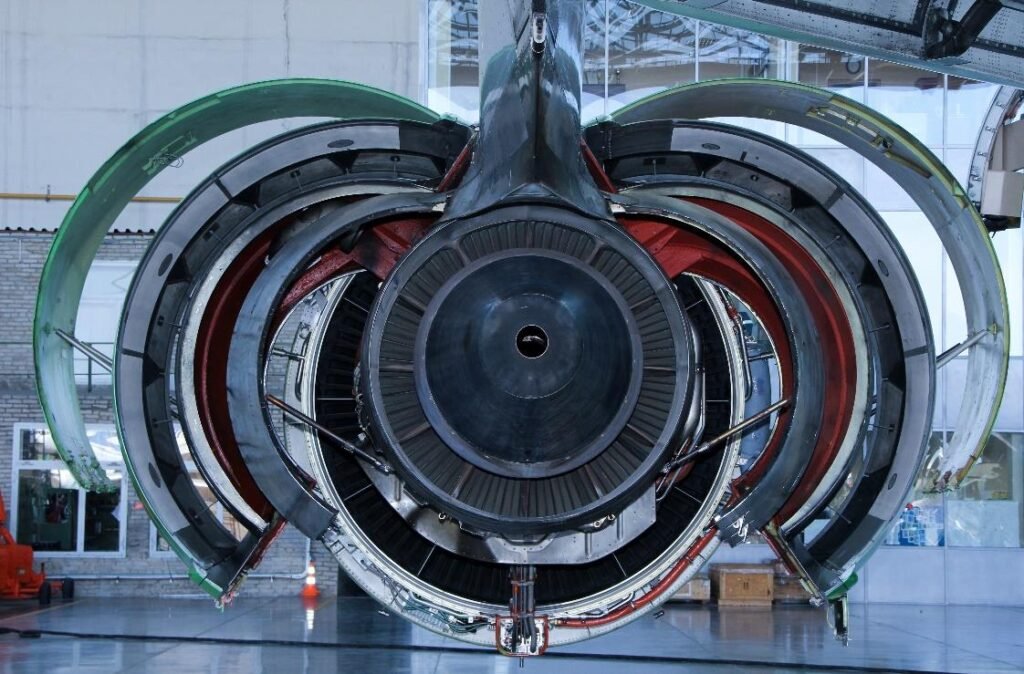

Aircraft Nacelle Photo

Traditionally, thermal barrier coatings (TBCs) shield metallic components in aerospace nacelle / thrust reversers from extreme heat, but their application to carbon fiber reinforced polymers (CFRPs) is a burgeoning field. Currently, research and development focus on understanding the long term performance of high-temperature resistant coatings on CFRPs under diverse operational conditions, including thermal cycling, humidity, and chemical exposure. This advancements in TBC technology for CFRP structures bring unique challenges on monitoring its thickness and coating bodings to optimize thermal insulation and minimize stress concentrations, thereby enhancing the component lifespan and overall reliability of composite materials in demanding environments. This evolution of thermal protection is crucial for advancing the use of CFRPs in next-generation applications.

Solution: Why Terahertz Now?

To understand the growing adoption of Terahertz (THz) technology, it’s essential to see the limitations of previous methods. Traditionally, thermal barrier coatings (TBCs) on metallic structures were often inspected using Eddy Current Testing (ECT) and other electromagnetic Non-Destructive Testing (NDT) techniques. These methods are effective for conductive materials, primarily ferrous and non-ferrous metals, and can provide information about TBC quality on those materials.

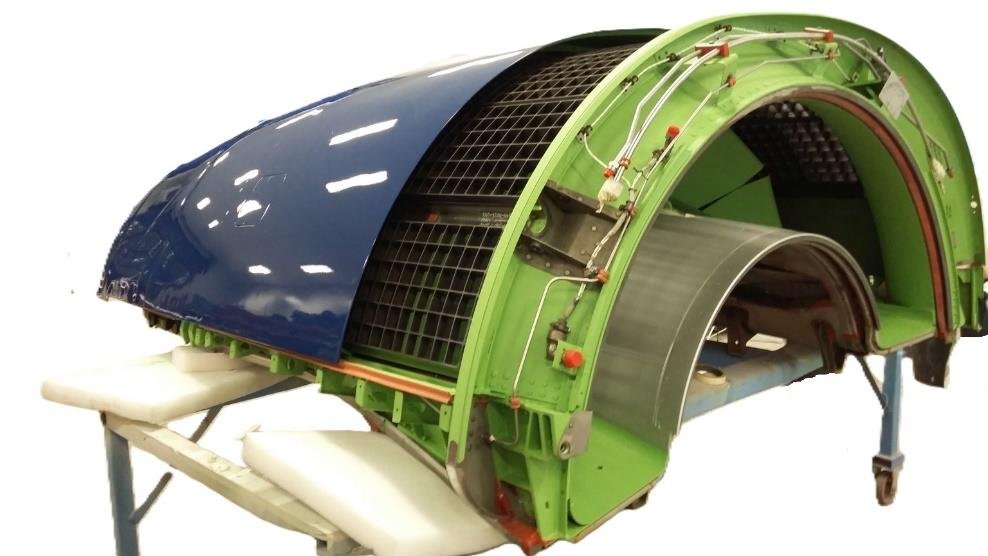

A Thrust Reverser with Thermal Barrier Coating on Metallic Surface

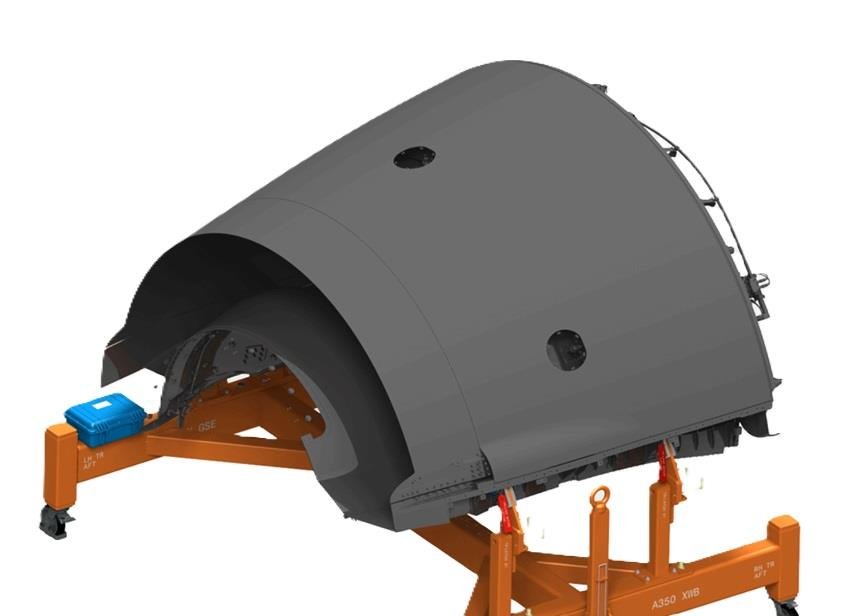

Aerospace manufacturers are continuously seeking ways to improve fuel efficiency and performance, driving the adoption of advanced materials. As a recent example from aerospace, the Jet Engine Nacelles/Thrust Reversers are located around the engine and therefore exposed to hot exhaust gases, engine heat and aerodynamic heat. Steel, Aluminium and Titanium and widely used due to high strength-to-weight ratio. Some pioneer industries working towards replacing these thrust reversers with Thermal Barrier Coated CFRP’s which directly leads to significant fuel efficiency.

With the increasing use of Carbon Fiber Reinforced Polymer (CFRP) in aerospace for weight reduction and performance improvements, a new challenge emerged. CFRP is significantly less conductive than metals and its conductivity is highly anisotropic. Therefore, conventional NDT techniques like Eddy Current Testing (ECT) and other electromagnetic methods are not effective for inspecting TBC thickness, density and bonding on CFRP.

Jet Engine Nacelles Photo with Metal and CFRP

Conclusion: A new method to measure TBC on CFRP

To address the limitations of traditional non-destructive testing (NDT), researchers have increasingly explored alternative technologies such as air-coupled ultrasonics, microwaves, and, notably, terahertz (THz) imaging. Terahertz technology, with its non-ionizing nature and non-contact testing capabilities, has demonstrated promising results in the quality control of advanced composite materials. Specifically, THz imaging’s ability to accurately measure thickness and detect sub-surface defects in single-layer and multi-layer thermal barrier coatings (TBCs) on carbon fiber reinforced polymer (CFRP) components, where the coating material’s refractive index ranges from 1.4 to 2.5, makes it a valuable tool for ensuring the structural integrity and reliability of these materials in emerging industries like aerospace and automotive, contributing to improved manufacturing processes and enhanced material characterization.

TeraNIM Measuring Thermal Barrier Coating Thickness on CFRP Substrate

TeraNIM – A Compact and Industrial Terahertz NDT System with 0.1 to 3.5 THz frequency bandwidth successfully measures TBC thickness on CFRP substrates. Thanks to non-contact testing, bring advantage to test and measure inaccessible areas in complex geometric CFRP parts. Terahertz Technology uniquely capable to measure TBC Thickness, Detect Defect and Density in single scan.

Key Benefits:

- Real-Time Results

- Micron Level Thickness Accuracy

- Feasible for Manual or Automated Measurements

- Capable 24x7 measurements

- Multi-Layer Thickness Measurements

- Defect Detection inImaging

- Integrated Camera to visualize measuring location

In today’s aerospace and space sector, the carbon fibre-reinforced plastics (CFRPs) plays a vital role because of its efficient properties such as high specific strength and stiffness, good fatigue, and chemical resistance which are much need for structures integrity. The majority of commercial airplanes are from Boeing 737, 747, 777, 787 and Airbus A320, A330, A350, A380. The goal of the International Civil Aviation Organization (ICAO) is to reduce aviation emissions by at least 50% by 2050. So, the development of composites with lightweight materials, namely CFRP, will increase. The modern aircrafts like Boeing 787 and Airbus A380 use more than 50% of CFRP in aircraft structures. To fully utilize on CFRP benefits under which thermal protection is crucial. The polymer matrix, which binds with the carbon fibers are vulnerable to heat-induced decomposition. Safeguarding CFRP from high temperatures and frictional forces are vital. CFRP is now being an integral part of advanced satellites, launch vehicles, and space exploration missions which will also need to sustain from drastic temperatures and frictional forces.

Traditionally, thermal barrier coatings (TBCs) shield metallic components in aerospace nacelle / thrust reversers from extreme heat, but their application to carbon fiber reinforced polymers (CFRPs) is a burgeoning field. Currently, research and development focus on understanding the long term performance of high-temperature resistant coatings on CFRPs under diverse operational conditions, including thermal cycling, humidity, and chemical exposure. This advancements in TBC technology for CFRP structures bring unique challenges on monitoring its thickness and coating bodings to optimize thermal insulation and minimize stress concentrations, thereby enhancing the component lifespan and overall reliability of composite materials in demanding environments. This evolution of thermal protection is crucial for advancing the use of CFRPs in next-generation applications.

In today’s aerospace and space sector, the carbon fibre-reinforced plastics (CFRPs) plays a vital role because of its efficient properties such as high specific strength and stiffness, good fatigue, and chemical resistance which are much need for structures integrity. The majority of commercial airplanes are from Boeing 737, 747, 777, 787 and Airbus A320, A330, A350, A380. The goal of the International Civil Aviation Organization (ICAO) is to reduce aviation emissions by at least 50% by 2050. So, the development of composites with lightweight materials, namely CFRP, will increase. The modern aircrafts like Boeing 787 and Airbus A380 use more than 50% of CFRP in aircraft structures. To fully utilize on CFRP benefits under which thermal protection is crucial. The polymer matrix, which binds with the carbon fibers are vulnerable to heat-induced decomposition. Safeguarding CFRP from high temperatures and frictional forces are vital. CFRP is now being an integral part of advanced satellites, launch vehicles, and space exploration missions which will also need to sustain from drastic temperatures and frictional forces.

Traditionally, thermal barrier coatings (TBCs) shield metallic components in aerospace nacelle / thrust reversers from extreme heat, but their application to carbon fiber reinforced polymers (CFRPs) is a burgeoning field. Currently, research and development focus on understanding the long term performance of high-temperature resistant coatings on CFRPs under diverse operational conditions, including thermal cycling, humidity, and chemical exposure. This advancements in TBC technology for CFRP structures bring unique challenges on monitoring its thickness and coating bodings to optimize thermal insulation and minimize stress concentrations, thereby enhancing the component lifespan and overall reliability of composite materials in demanding environments. This evolution of thermal protection is crucial for advancing the use of CFRPs in next-generation applications.