Non-Metallic Liner Inspection on Type IV Cylinder with Terahertz

Application – Sub-Surface Defects on GFRP Samples

CURRENT SITUATION:

The natural gas found its way to the top especially in terms of automobile fuel alternative because of its availability and cleanliness compared to petrol and diesel. These improvements created a new potential for the natural gas industries including the high pressure cylinder manufacturers. The need for bigger cylinders with more capacity for increasing the range of automobiles resulted in the mass production of these cylinders.

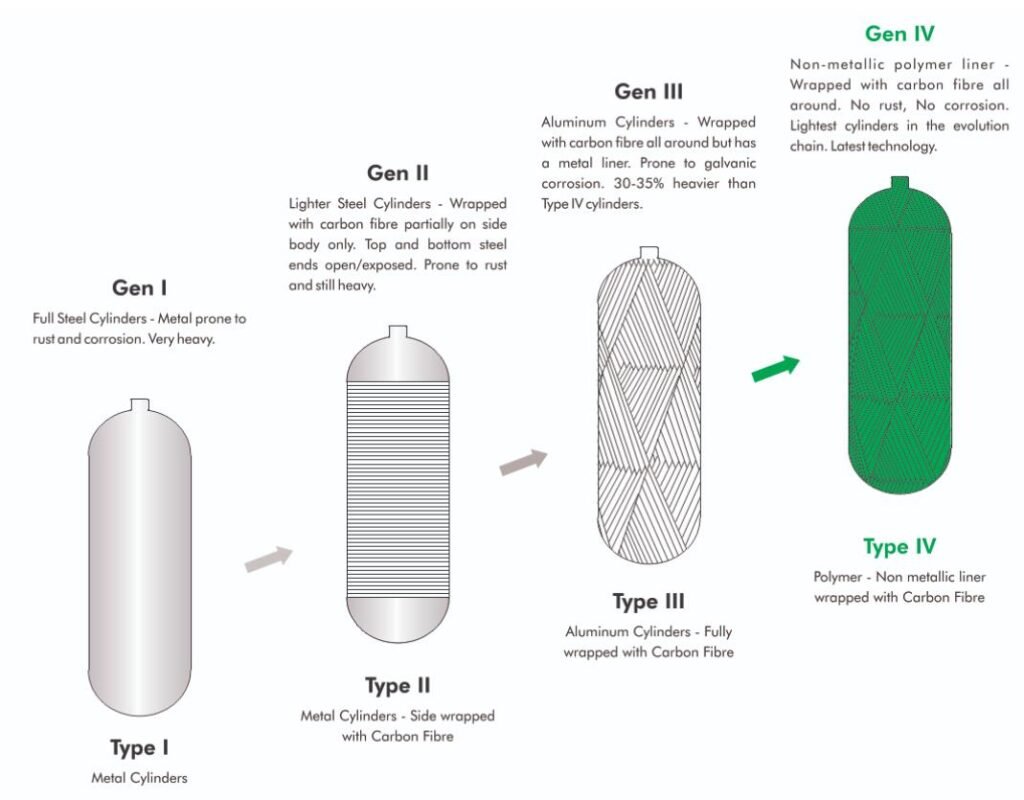

There are 4 types of CNG (Compressed Natural Gas) cylinders to transport high-pressure natural gas.

Glass Fiber-Reinforced Polymer (GFRP) composites have several advantages combining lightweight, higher strength, low thermal

conductivity, high resistance to corrosion and good thermal and electrical insulation performances. Due to the above properties, it has been widely utilized in various industries such as aerospace, missile industry, oil and gas and construction industry.

PROPOSED SOLUTION:

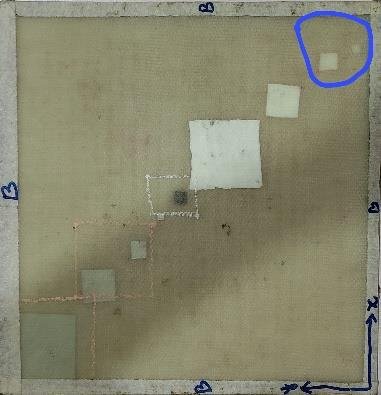

Due to its complex design and manufacturing process, it is susceptible to various internal defects and damages, voids and delamination. In the below GFRP sample, we have embedded with external materials such as Aluminum, mild steel and Teflon tape.

(a) Visible image of GFRP sample with Aluminium, mild steel and teflon inserts (b) THz image of GFRP sample (marked area)

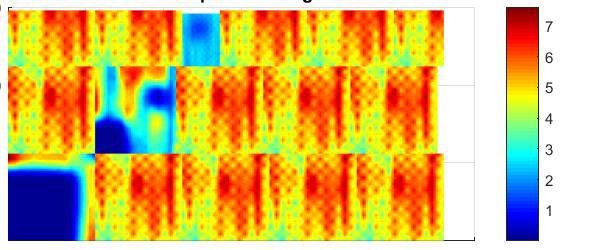

The imaging can be done with TeraNIM device and Probe Head. The entire image has been obtained by calculating the average intensity at each pixel. The Aluminium inserts have been clearly shown as mentioned in the figure. Teflon tape and GFRP samples have similar transmission intensity and hence has not been imaged in this figure. Walter et al. has utilized the THz-TDS system to detect, localize and evaluate hidden multi-dimension effects in multilayered GFRP structures as shown in Figure 3.

Time traces of the detected reflected THz signal in the time domain, with all three levels of delamination

(a)

(b)

CONCLUSION:

Terahertz Technology is capable of testing Non-Metallic liners on CFRP Type IV Cylinder for Thickness, Voids, Inclusions, CFRP-GFRP Bonding, Delamination and Material Properties (effective refractive index and absorption coefficients).